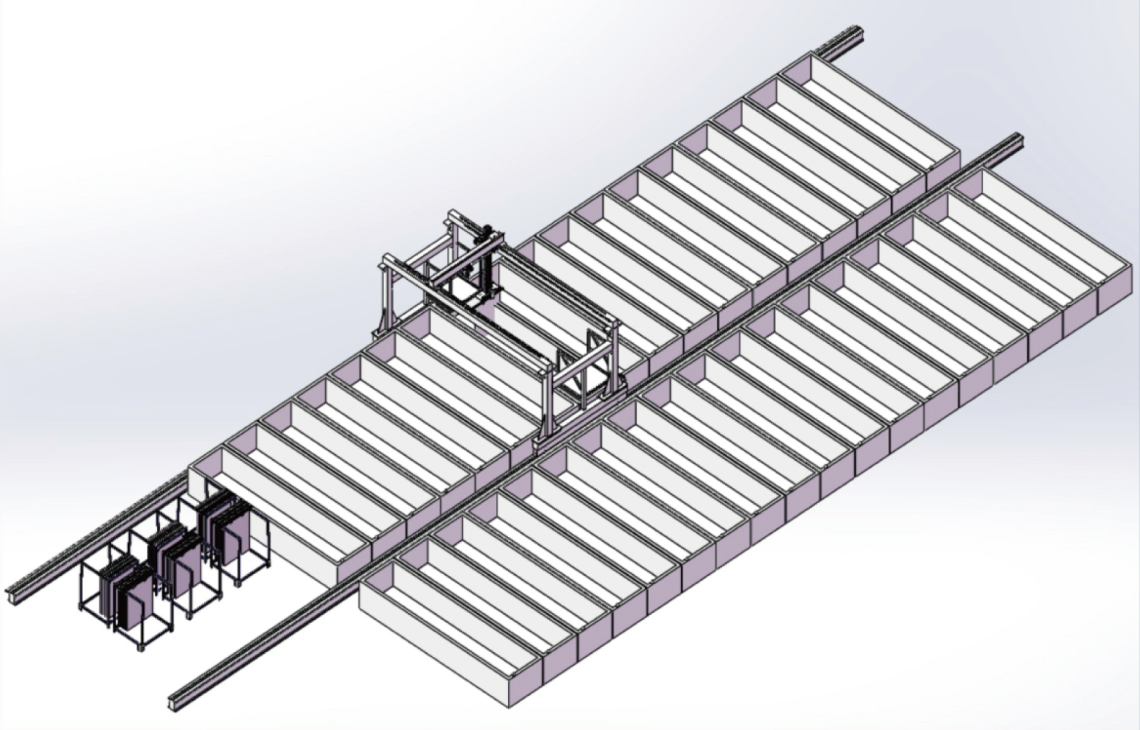

Short-Circuit Cathode Plate

Automatic Replacement Device

In copper electrolysis production, handling short-circuit cathode plates has always been a labor-intensive task. Traditional manual processing methods are not only time-consuming and laborious but also pose safety risks. To address this, we have introduced the Short-Circuit Cathode Plate Automatic Replacement Device, bringing intelligent transformation to electrolysis production.

- Automatic replacement,

- intelligent transformation

- Automatic replacement,

- intelligent transformation

Short-Circuit Cathode Plate Automatic Replacement Device · 5 Major Product Features

1. From Manual to Automated

Transitioning from labor-intensive manual handling to intelligent automatic replacement significantly reduces the workload of staff and improves production efficiency.

2. Intelligent Recognition and Linkage

Closely integrated with the tank surface circuit fault monitoring device, it monitors in real time and automatically replaces the cathode plate based on fault conditions.

3. Customized Installation

Customized installation based on the actual site conditions, ensuring a perfect integration of the device with the production line.

4. Safety First

Not only does it improve efficiency, but it also significantly enhances production safety, reducing the risk of safety incidents caused by human operational errors.

5. Significant Economic Benefits

In the long run, the automatic replacement device will save a considerable amount of manpower and time costs for enterprises, bringing significant economic benefits.