Cathode Copper Surface Particle

Automatic Trimming Device

The Cathode Copper Surface Particle Automatic Trimming Device is designed to meet the actual production needs of smelting plants. To ensure the produced cathode copper meets the strict standards of Grade A copper, we have launched this efficient device that combines 3D visual inspection with intelligent trimming.

- Grade A Copper Standard

- Enhances Efficiency and Precision

- 3D Intelligent Device

- Grade A Copper Standard

- 3D Intelligent Device

- Enhances Efficiency and Precision

Cathode Copper Surface Particle Automatic Trimming Device · Core Functions

Compared to traditional manual trimming, it significantly improves efficiency and precision, ensuring each copper plate reaches the industry’s top quality.

Fully Automatic Removal

Capable of covering the entire plate range, achieving full automatic milling of copper particles

High Efficiency Trimming

The average milling efficiency only requires 3-10 minutes per plate, with a milling depth of up to 2-3mm

Adaptive Trimming

Regardless of how the copper plate surface bends or deforms, the system can intelligently adjust the milling cutter distance, ensuring precise milling

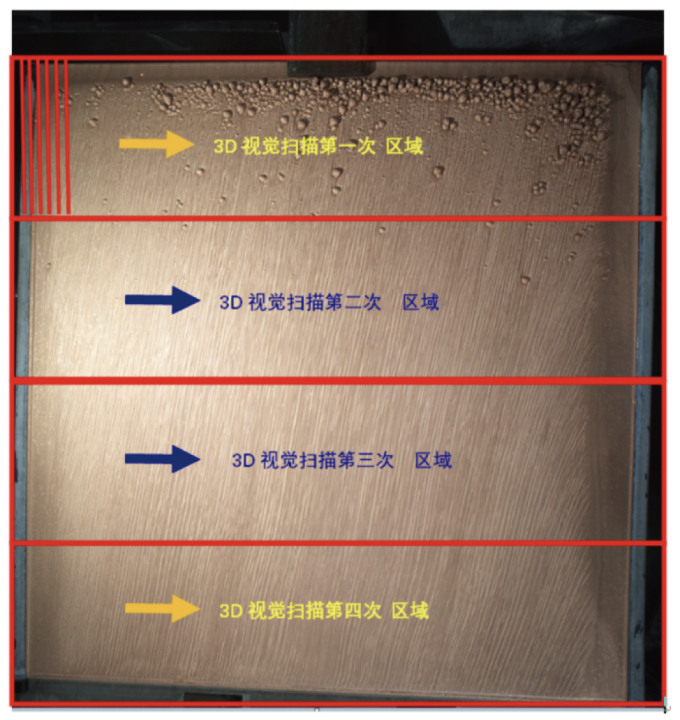

Intelligent Detection

Automatically detects the distribution and height of copper particles, determining the optimal cutting range and parameters

Dynamic Adjustment

Dynamically adjusts the milling feed and speed based on the height of copper particles, ensuring the best balance between trimming effect and efficiency

Achieving the Perfect Standard of Grade A Copper

Efficient Trimming for Perfection

Efficient Trimming for Perfection

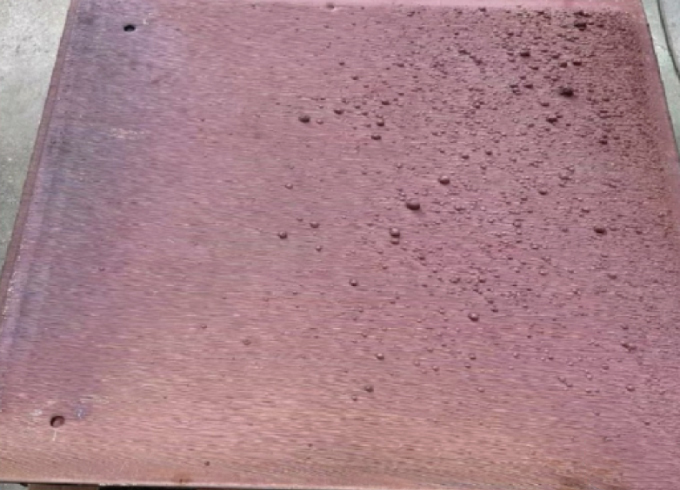

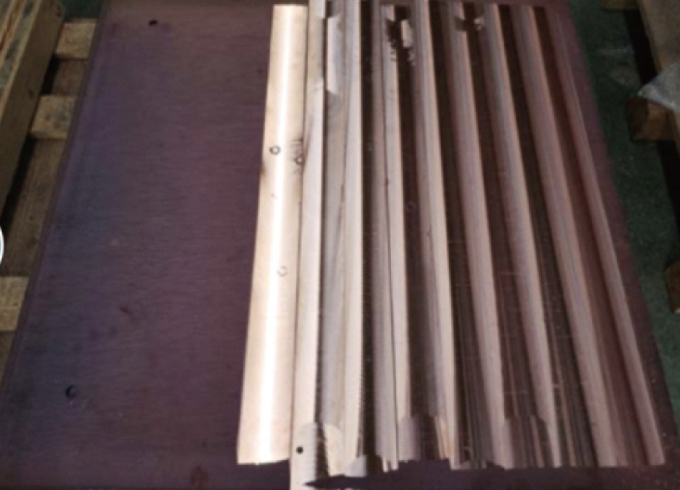

Before Correction After Trimming