Cathode Copper Surface Quality

Detection System

Cathode Copper Surface Quality Detection System

Utilizing convolution operations to obtain the feature map of preprocessed images, through the multi-resolution convolution and fusion of the pyramid pooling module, the network segments background pixels and copper particle pixel categories. With copper particle image training, once the network recognition precision of copper particle pixels reaches the specified value, a network parameter file is generated for use in the actual online copper particle detection system.

- Recognition Range

- Recognition Judgment

- Quality Statistics

- Output Method

- Recognition Range

- Recognition Judgment

- Quality Statistics

- Output Method

Accurate

Identification

Intelligent Judgment

Highly Customizable

Cathode Copper Surface Quality Detection System · Main Functions

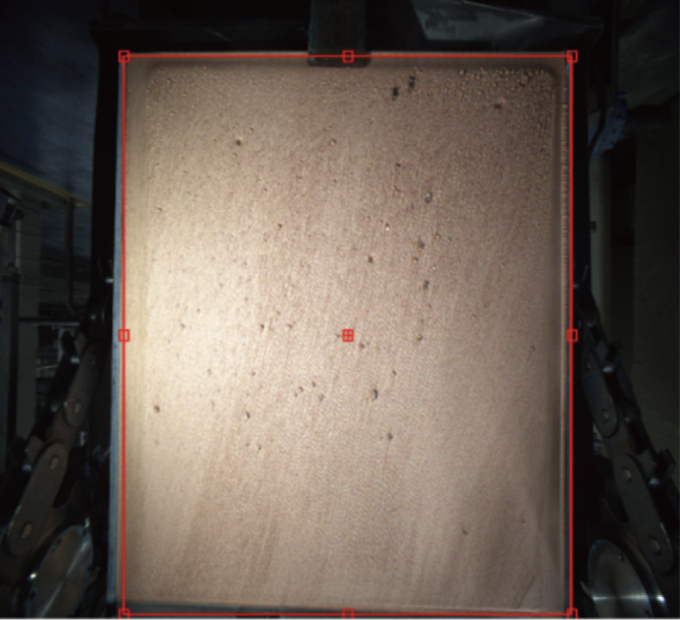

- Recognition Range

1. Identifies the phenomenon of partial or whole cathode plates not growing copper and calculates the corresponding area;

2. The system can recognize round-headed particles, calculate their size, and count their number and area;

3. Recognition and statistics of irregular-shaped particles (e.g., elliptical and other non-circular shapes);

- Recognition Judgment

1. Quick statistics and classification of the total number of particles on the entire plate;

2. For dispersed particles, the system uses a count and area statistics judgment;

3. For dense particles, the system uses an area judgment;

- Quality Statistics

Automatically statistics the size, number, and area ratio of particles in different intervals, such as the number and area ratio of 3–5mm, 5-10mm, 10-20mm, with specific size intervals being editable; (Six intervals reserved, enabling the number of intervals based on site requirements)

- Output Method

Supports data storage and export of detection results and photographs.

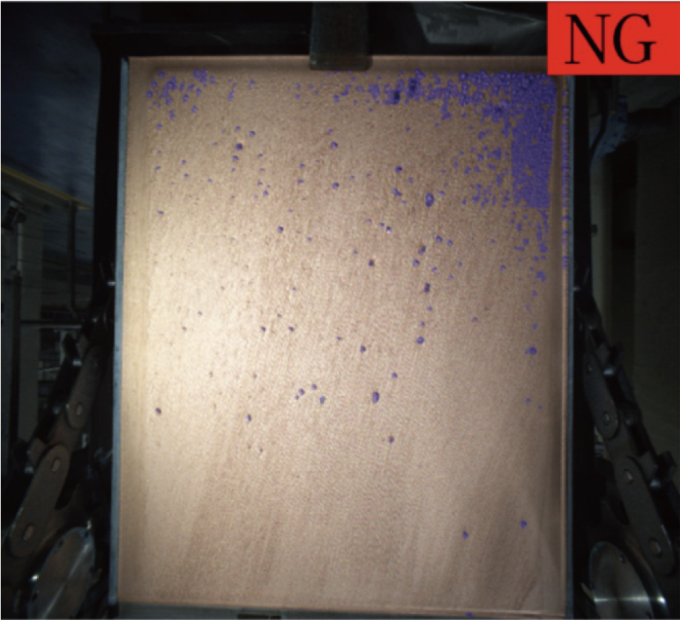

- Recognition Range

1. Identifies the phenomenon of partial or whole cathode plates not growing copper and calculates the corresponding area;

2. The system can recognize round-headed particles, calculate their size, and count their number and area;

3. Recognition and statistics of irregular-shaped particles (e.g., elliptical and other non-circular shapes);

- Recognition Judgment

1. Quick statistics and classification of the total number of particles on the entire plate;

2. For dispersed particles, the system uses a count and area statistics judgment;

3. For dense particles, the system uses an area judgment;

- Quality Statistics

Automatically statistics the size, number, and area ratio of particles in different intervals, such as the number and area ratio of 3–5mm, 5-10mm, 10-20mm, with specific size intervals being editable; (Six intervals reserved, enabling the number of intervals based on site requirements)

- Output Method

Supports data storage and export of detection results and photographs.